- Case Maker Column

- QZFM-700/900 Automatic Case Making & Inner Laminating Machine

- ZFM-700A/900A/1000A . Automatic Case Making Machine

- ZFM-700B/900B Automatic Case Making Machine

- FM-700/900/1000 Semi-automatic Case Making Machine

- ZTC-700A/900A/1000A . Automatic Inner Laminating Machine

- ZTC-700B/900B Automatic Inner Laminating Machine

- ZTC-700C/900C/1000C . Automatic Inner Laminating Machine

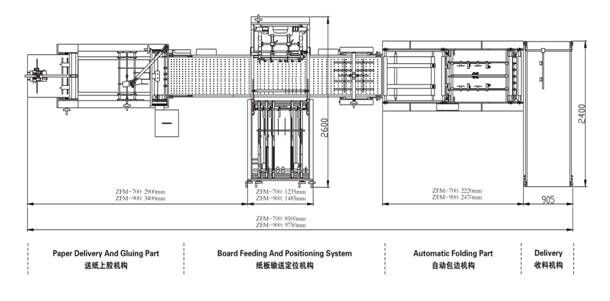

Automatic Case Making Machine

ZFM-700/900/1000/1350A Automatic Case Making Machine can be applied for producing hard covers, folders, calendars, albums, puzzle boards, lever arch files, document files, cell phone boxes, moon cake boxes, etc. We do not simply provide machines, but help the customers make full use of their values.

Main Configurations:

1. Japanese Panasonic PLC, Frequency converter, Temperature controller

2. Japanese Panasonic servo motor

3. Korean NSK moto unit

4. Taiwan HIWIN linear slideway

5. Japanese CKD pneumatic components

6. German SICK photo sensor

7. Advanced wear-resistant automotive transmission shaft

8. French Schneider electric

9. Taiwan ADLEE DC motor

Main Patented Technology Features:

1. Automatic correcting system, which enhances the board positioning accuracy

Patent No:ZL200820123683.X

Using of this patent, controls board positioning accuracy strictly within 0.5mm, which solves the

bottleneck problem of inaccurate positioning of hardcovers in this industry.

2. Cycle board delivery, which improves delivery speed

Patent No:ZL200820127551.4

The usage of the patent changes the situation that there is only one set of feeder delivery system in

content market, and it adopts 2 set feeder system to deliver in cycle, so that the production speed has

been improved 20%-30%

3. Adopting platform-based automatic folding system Patent No:ZL201020279882.7

This patent makes edge-folding more firm, which reduces surface scratches heavily, and makes the

finished products more beautiful.

1. Positioning Accuracy

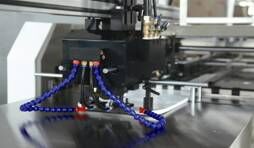

The ZFM-700/900/1000/1350A Automatic Case Making machine adopts three-point photoelectric positioning system(as the picture below shows), which makes the positioning accuracy at ±0.25mm.

2. Servo motor quantity

Our ZFM-700/900/1000/1350A Automatic Case Making machine adopts 4 sets of Panasonic servo motor, 3 sets is for positioning , and another set is for board feeding. That’s why our machine can make the positioning mistake less than 0.25mm.

3. Irregular-shape making

Our ZFM-700/900/1000/1350A Automatic Case Making machine can make the one-side irregular shape product ( including round , triangle , wave shape etc.) without any extra mould. However, machines from other manufacturers normally need to install different moulds to do different irregular-shape product.

|

Model |

ZFM-700A |

ZFM-900A |

ZFM-1000A |

ZFM-1350A |

|

Maximum size |

450mm×720mm |

450mm×950mm |

600mm×1050mm |

600mm×1350mm |

|

Minimum size |

90mm×180mm |

90mm×180mm |

140mm×240mm |

140mm×240mm |

|

Board thickness |

1.0-3.0mm |

1.0-3.0mm |

1.0-3.0mm |

1.0-3.0mm |

|

Paper weight |

105-210g |

105-210g |

105-210g |

105-210g |

|

Maximum speed |

20-30Pieces/min |

20-30Pieces/min |

15-25Pieces/min |

10-20Pieces/min |

|

Power supply |

16KW/380V |

17.5KW/380V |

18KW/380V |

19KW/380V |

|

Dimension (L×W×H) |

8500×2600×1500mm |

9750×2600×1500mm |

10440×3000×1500mm |

11500×3000×1500mm |

|

Machine weight |

3500kg |

4000kg |

5000kg |

6000kg |

|

Positioning accuracy |

±0.25mm |

±0.25mm |

±0.5mm |

±0.5mm |

|

Boards amount |

1-6Pieces |

1-6Pieces |

1-6Pieces |

1-5Pieces |

|

Minimum spine width |

8mm |

8mm |

8mm |

8mm |

|

Minimum side-board width |

25mm |

25mm |

25mm |

25mm |

Remark:

1.The maximum and minimum size of the covers are subjected to those of the paper and the quality of the paper.

2. The production speed is 20-30 pieces/min, but it may be affected be the cover sizes,the material and quality of paper and board.

Board delivery system Feeder system

Gluing system Platform based folding system

Delivery system three-point photoelectric positioning system

making the positioning inaccuracy ±0.25mm

Performance Characteristics

1. Japanese Panasonic PLC and servo motor make the machine performance

more stable and accurate;

2. Imported Korean box-type linear guide ensures the high stability of

the machine;

3. Japanese Panasonic servo drive system reduces the maintenance;

4. Automatic paper feeder, angle pressing and folding system make highly

consistent products;

5. Special suction nozzle reduces double paper feeding;

6. Double sheets detection system avoids double paper feeding and

reduces material waste;

7. The vacuum blower under the belt conveyor provides suction and makes

paper flat on the conveyor;

8. Automatic paper suction and blow. The snifter valve solves the

problem of short service life of the electronic air valve;

9. The board feeding unit adopts imported servo motor. The feature of

starting slowly, speeding up in the middle and slowing down in the end solves

the problem of low quality of board feeding.

10. The servo motor also makes the board changing more convenient to operate. Type the size of board into the touch screen and press the board-pushing-debugging button.

11. The space between two boards can be adjusted accurately by

adjusting handle;

12. The double suction nozzle technology avoids the problem of deflection

in alternating the boards;

13. The Panasonic servo control system and photoelectric sensor enhance

the positioning accuracy greatly;

14. Manual-like folding device increases the range of application, enabling

it to produce products with narrow front or back boards (minimum 25mm);

15. Optical photoelectric devices and servo control system make board

changing and speed governing more convenient.